What are KGH’s specialties?

”KGH was founded in 1986 as a light bead pearl clasp company”, says Tsachi Herzog, owner and son of one of KGH’s founders, Avraham Herzog. “The manufacturing of pearl clasps is essentially a niche field in the pearl industry. It requires specialized technology and know-how.

The clasp must feature a reliable, long-standing, simple and aesthetic mechanism. Clasps have different mechanisms, and KGH has a permanent collection of seven types of locks, and additional locks are manufactured as the need arises. The type of lock is determined according to the price range of the individual product. A basic product such as a freshwater pearl necklace, which is the most common type of cultured pearls, will feature a simple mechanism with a tongue clasp. A necklace with South Sea pearls, which are extremely rare and therefore more expensive, will feature a more sophisticated clasp mechanism”.

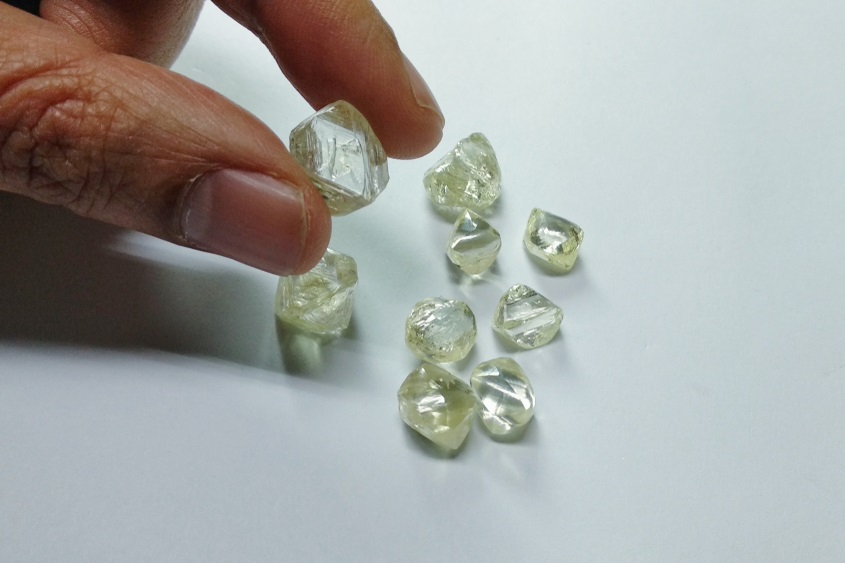

“In addition to technologically complex clasps, we have begun to design and manufacture gold jewelry set with diamonds and pearls. All products are made in-house, in our facility in the Israeli Diamond Complex in Ramat Gan, Israel. This allows us to work closely with diamantaires as well as suppliers”.

What makes KGH special in the pearl industry?

”The pearl industry is as diverse and complex as the diamond industry. Pearl wholesalers go through years of training until they become experts in the field, and can really understand a pearl, estimate its worth and market it. Here is where we come in. KGH combines innovation with Israeli design, always adhering to high quality assurance, as well as professional assistance and service to our clients”.

What does the KGH marketing division focus on?

”We have made several changes over the last years. In the past, we would participate in approximately ten jewelry shows every year while as today, we focus on social media marketing and promotion through our website. We have done a complete “website overhaul”, making it responsive for all platforms, and we keep it up-to-date at all times. We also have a Facebook page, which we keep updating prior and during shows”.

“We still participate in shows, but we have narrowed down our participation to the three major global shows – two in Hong Kong, and the third in Las Vegas. In addition, we work closely with sales persons and partners in other Israeli companies that help market jewels abroad. This is an initiative of the Ministry of Economy, which aims to market several companies under one roof”.

What are your major target markets?

”In early days, our primary market was the United States. In our marketing strategy there, we relied on founder’s Gabriel Konig’s contacts. Konig was the in-house designer for Omar Torres, a well-known American designer. From there on, our business grew. In the beginning of the 90s we were approached by the Germans, who wished to purchase pearl clasps, and Germany quickly became as big a market as the US. We began working in Japan after participating in our first IJT show in Tokyo. Until the recession, Japan was a major market. Today, our major markets are the US, Europe and Asia”.

How did you join KGH?

Gabriel Konig and my father Avraham were cousins who came to Israel together after the Holocaust. They began to work in jewelry related factory that has since closed. They founded KGH from a two-room apartment in the city of Givatayim. From the start, the company sought to export, and marketing in Israel was virtually nonexistent. In 1990, we expanded and slowly become to be what we are today. I started working in the company after my release from the army. I didn’t really know what I wanted to do professionally, and “working for dad” for a while made sense. Sadly, my father passed away and I decided to engage in the business in earnest. I found it to be an enriching experience.

What do like most about KGH?

I like the creative process involved in every product we make, as well as the use of advanced technologies. In 2008 we integrated a 3D technology, and made all design computer-based. Today, all our designs are done with this software and 3D printers. When 21st century high-tech and hand sketches combine, the process is fascinating.

Click on the Gallery to see more KGH designs