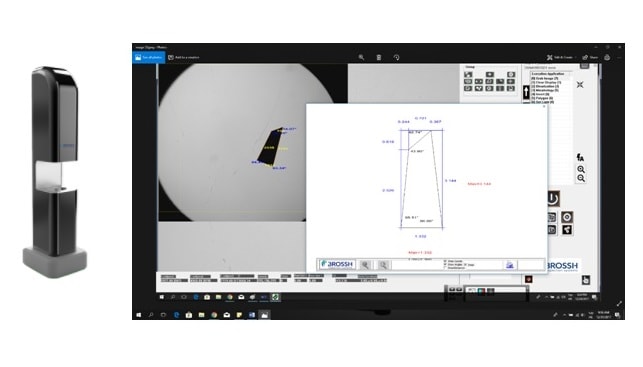

Israel-based company BROSSH inspection systems, which specializes in hands-free optical measurement solutions, has recently developed a new device, small and fully-automated, to measure the dimensions of small diamonds.

BROSSH focuses on measurement solutions based on Machine Vision, in cases where operators need to be replaced with more precise measurements. The company provides automated machines which save time and supply objective measurements, independent of the skill of the operator.

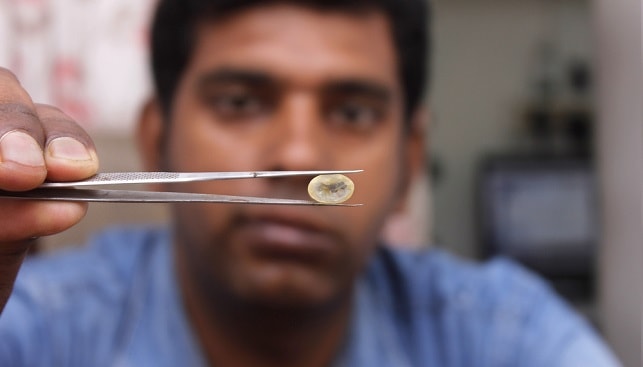

BROSSH’s new device is a compact tool, fit for industrial environments. Once the diamond is set on the measuring surface, it is identified and measured. The diamond’s exact dimensions appear on the screen, which the operator can then print on a sticker. The tool does not necessitate training, and the measurement accuracy is +/-2 microns.

Founder of BROSSH, Michael Geffen, explains: “A year ago, we were approached by an owner of a diamond polishing factory, and he challenged us to find a solution for measuring cut diamonds intended to be later set in watches. Most measuring tools in the market demand the design of a measurement software. That means that you have to know what you’re going to be measuring, and then divide the measuring tools for each image. These solutions do not fit the needs of the diamond manufacturer, or the polisher who needs to know precise measurements in each stage of the polishing process. He or she needs more than just measuring the diamond in the final stage of polishing. In addition, the finished product – the polished diamond before it is set – is not mass produced, but generally custom-made for a specific watch maker”.

Geffen summarizes: “We’ve had two set ups of the new device so far in diamond companies. In both, adding to precise measurements that do not demand any training, we found that it saves significant manpower, since the polisher does not need to take the diamond to the measuring station several times in the process. He uses the BROSSH device, which is just next to him in his or her station, and provides him or her with continuous, available feedback”.