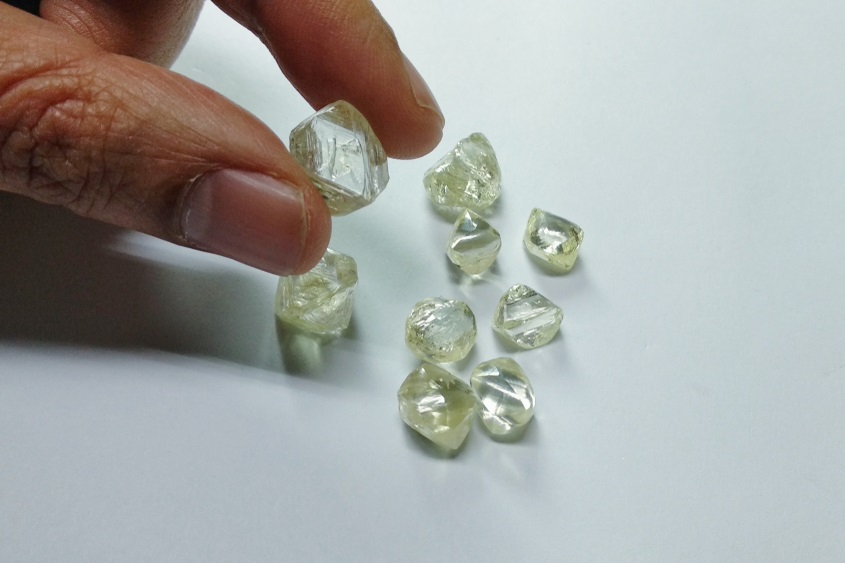

An advanced “one-stop-shop” for diamond manufacturing, recently opened near the Israel diamond complex in Ramat Gan, is the first step in an ambitious plan by Israeli diamond leaders to bring back a large part of the offshore diamond polishing business to the country. The plan is being supported by the Israel Diamond Exchange (IDE), the Israel Diamond Manufacturers Association (IsDMA) and the Israel Diamond Institute Group of Companies (IDI).

The new 400-square-meter manufacturing center provides a subsidized work environment for up to 100 polishers, access to an abundance of advanced technological systems, including the Sarine Galaxy machine, laser-cutting and automatic-round polishing, with teaching staff on site. The idea is to offer IDE members, especially small and medium sized companies, the ability to polish their rough diamonds in Israel, at prices competitive with or even cheaper than offshore locations.

A Change of Direction

The establishment of modern manufacturing facility is being led by IDE’s industry committee chairman, Yoram Dvash, with the support of IDE’s president, Shmuel Schnitzer, IsDMA’s president, Jacob Korn, and IDI’s chairman, Moti Ganz.

Dvash, whose own diamond company manufactures solely in Israel, believes that manufacturing is essential to maintaining Israel’s status as a leading world diamond hub. He said, “Our objective is to change the direction. We want to bring Israel back to being a manufacturing center. This is a first step to expanding manufacturing and to make it younger and smarter.” Dvash added that when the facility takes off, he’ll look into expanding it and adding more manufacturing capacity. “We believe that a large percentage Israel’s diamond manufacturing will be done by the center,” he said.

Dvash said that he believes that for the Israeli industry, the modern facility can offer an alternative to the “cheap” manufacturing centers in India and China. “Due to our technology and the type of rough diamonds we polish, the difference in labor costs between Israel and China as a share of the total manufacturing cost is insignificant. Take into account costs of shipping, insuring and the time it takes to ship diamonds from manufacturing centers to trading centers and the price differential for top quality diamonds is negligible,” he added.

Training New Polishers

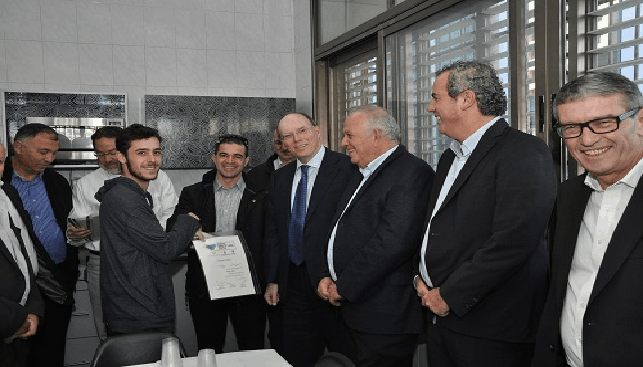

In addition, the manufacturing center houses an academy to train new polishers, with a special focus on the younger generation, in order to establish a community of younger diamond polishers. The academy offers several courses a year, training a total of 60 new polishers in the first year. The students are given a stipend during the course and are guaranteed a job when they graduate. The training program is being run in conjunction with Amal educational network and is being partially supported by the Israeli government.

Ripple Effect

Dvash said that he believes that the steps taken so far will have a ripple effect. “I have received several calls from diamantaires from Israel and abroad who have asked us to help them set up manufacturing facilities in Israel. There’s no doubt that this is upgrading the entire diamond manufacturing industry in Israel,” he said.