A machine for rotating and smoothing out girdles had already been developed by the diamond industry in Israel in the 1960s, even before the development of the automatic cutting machine. The former was developed as part of an effort to improve the cutting, and it allows for manual cutting of a round diamond. A diamond that does not end up with a nice symmetric round shape after manual cutting, due to its shape or due to falling out of calibration, is sent to have its round shape corrected and improved by a Roundist Machine.

How Does a Roundist Polishing Machine Work?

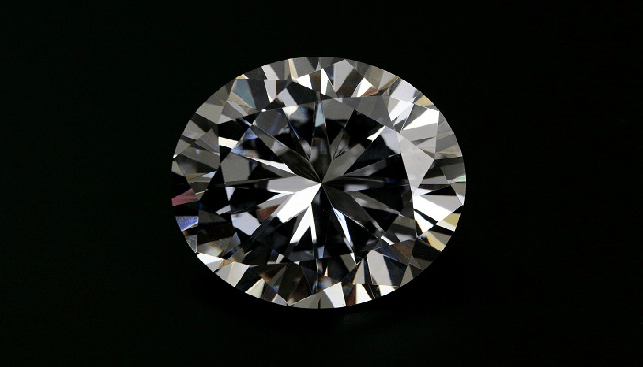

The machine is based upon a simple smart principle: the sharpening wheel, which is covered with diamond dust, spins around just like a blade-sharpening machine, while the round diamond to be polished is brought towards it. The diamond is rotated freely while brought into contact with the sharpening wheel. The complimentary rotation creates a roundist – a nice smooth girdle on the diamond.

Despite the fact that the machine did not polish the roundist in the accepted method, as is the case with large diamonds, but instead invented a new cutting action, the machine received the name “Roundist Polishing Machine”.

The machine was in great demand and was very helpful to diamond cutters until the automatic cutting machine came into popular use.