The action of sawing separates a diamond crystal into two parts. Often a diamond must be cut into two parts, or sometimes even more.

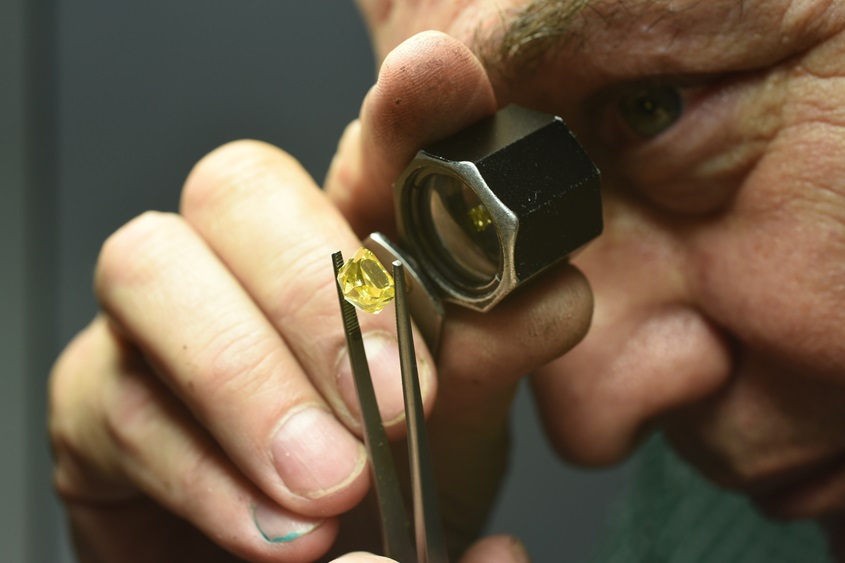

The aim of sawing is to maximize the amount of rough diamond in relation to the finished polished diamond. The factors in the decision-making are the outward appearance of the crystal and the possible ways to saw it, based on the amount of interior flaws and the monetary value that the different parts will be worth after sawing.

The two main accepted ways to separate a diamond into parts are cleaving and sawing. The point of sawing is determined by the pointer, taking into account directions that are appropriate for the sawing action.

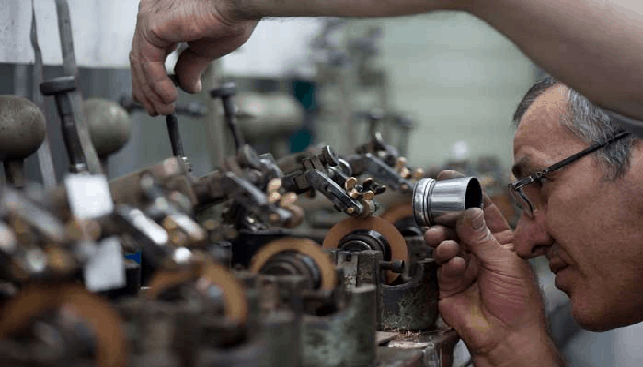

The trajectories in the structure of the diamond crystal are called plane 100 and plane 110, and they are also the possible trajectories for polishing the diamond. The sawing is carried out with a thin bronze disc whose rim is coated with diamond dust, which spins at high speed and penetrates the diamond crystal, which is lowered down onto it using a special arm on the sawing machine. Nowadays, a new sawing method is being developed using laser rays, which are faster and allow one to easily overcome stones which are especially difficult and problematic.